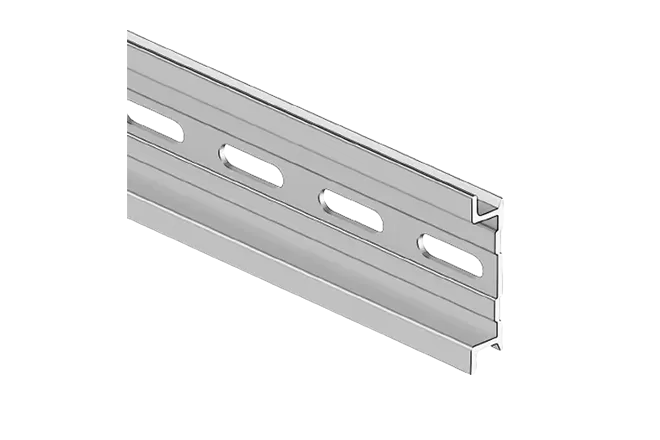

EASCO's Din Rails are engineered to provide unparalleled stability and versatility for your electrical and automation needs. Crafted from high-grade, corrosion-resistant materials, these Din Rails ensure long-lasting durability even in the most demanding environments. The precision-engineered design allows for easy installation and secure mounting of various electrical components, enhancing system reliability and safety. With a focus on user convenience, EASCO's Din Rails feature pre-punched holes for effortless alignment and compatibility with a wide range of accessories. Whether for industrial automation, control panels, or distribution boards, EASCO's Din Rails deliver exceptional performance and adaptability.

To ensure proper grounding with DIN rails, always verify that the rail—recommended by leading DIN rail manufacturers for quality compliance—is securely mounted to a conductive surface within the enclosure or panel. Use grounding brackets or clips specifically designed for Din Rails to establish a reliable electrical connection. Ensure that all grounding points are free from paint, rust, or any insulating materials that could impede conductivity. Connect the Din Rail to the main grounding busbar using appropriate grounding wires and terminals. Regularly inspect the grounding connections for signs of wear or corrosion to maintain electrical safety and compliance with industry standards such as IEC/EN 60715.

Ensuring the longevity of your Din Rails involves regular maintenance and proper handling. Periodically inspect the rails for signs of corrosion, wear, or physical damage. Clean the rails using a non-abrasive cloth and a mild cleaning solution to remove dust and debris. Avoid using harsh chemicals that could degrade the material. Ensure that all mounted components are securely fastened to prevent undue stress on the rail. If the Din Rails are installed in harsh environments, consider using protective coatings or enclosures to shield them from corrosive elements. Regular maintenance checks will help extend the lifespan and reliability of your Din Rails.